AISI 4140 Steel Bar

Buy AISI 4140 Steel Bar, also known as SAE 4140 Steel Bar, AISI 4140 Steel Bar is a chromium-molybdenum alloy steel with high strength, high toughness and excellent heat treatment performance. If you need to purchase and want to know the price, please feel free to ask and we will reply you in time. AISI 4140 Round Steel Bar has good heat treatment performance, and its structure and performance can be changed by heat treatment processes such as quenching, tempering, annealing and normalizing. Heat treatment can further improve its hardness, strength and wear resistance to meet different engineering needs.

Description

Product Description

Buy AISI 4140 Steel Bar, also known as SAE 4140 Steel Bar, AISI 4140 Steel Bar is a chromium-molybdenum alloy steel with high strength, high toughness and excellent heat treatment performance. If you need to purchase and want to know the price, please feel free to ask and we will reply you in time. AISI 4140 Round Steel Bar has good heat treatment performance, and its structure and performance can be changed by heat treatment processes such as quenching, tempering, annealing and normalizing. Heat treatment can further improve its hardness, strength and wear resistance to meet different engineering needs.

AISI 4140 Steel Rod chemical composition includes 0.38-0.43% carbon, 0.75-1.00% manganese, 0.80-1.10% chromium and 0.15-0.25% molybdenum, etc.

AISI 4140 Steel Bar Mechanical Properties

The mechanical properties of AISI 4140 Steel Bars are very excellent, as follows:

Tensile Strength: 455-1598 MPa

Yield Strength: 338-986 MPa

Elongation: 7-21%

Hardness: 196-397 HB

These properties make AISI 4140 Steel Round Bar suitable for applications that require high strength and good toughness.

Heat Treatment Properties

Application Areas

Due to the high strength, high toughness and excellent heat treatment properties of AISI 4140 Steel Bar, it is widely used in the following fields:

Gears, Shafts and Drills: In the shipbuilding and oil drilling industries, AISI 4140 Steel Round Rod is used to manufacture gears, drills and shafts due to its corrosion resistance and high strength.

Machine Parts: AISI 4140 Steel Bar is suitable for manufacturing hard machine parts due to its good wear resistance and ductility.

High-load parts: such as large gears used for locomotive traction, supercharger transmission gears, rear axles, connecting rods and spring clips that are subject to extremely high loads, etc.

Standards

| Brand | Carbon Steel |

| Q195、Q215A、Q215B、Q235A、 | 1.5~ 25.4 ×780~2100× 2000 ~12000 |

| Q235B、Q235C、Q235D | |

| SS330、SS400 | 1.5~25.4 ×780~2100× 2000 ~ 12000 |

| S235JR+AR、S235J0+AR、S275JR+AR、S275J0+AR | |

| SPHC、SPHD | 1.5~14.0×780~2100× 2000 ~ 12000 |

| SPHE | 1.5 ~ 6.0 ×780 ~2100× 2000 ~ 12000 |

| DD11、DD12、DD13 | 1.5 ~ 8.0 ×780 ~2100× 2000 ~ 12000 |

| HCP |

| Brand | Appropriate standard |

| Q195、Q215A ~ Q235D | GB/T 709 |

| SS330、SS400 | JIS G 3193 |

| S235JR+AR、S235J0+AR | EN 10029 |

| S275JR+AR、S275J0+AR | |

| SPHC、SPHD、SPHE | JIS G3193 |

| DD11、DD12、DD13 | EN 10051 |

| HCP | WJX(RZ)571 |

| S45C | 0.42~0.48 | 0.60~0.90 | 0.15~0.35 | ≤0.03 | ≤0.03 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | JIS G4051-2005 |

| S20C | 0.18~0.23 | 0.30~0.60 | 0.15~0.35 | ≤0.03 | ≤0.035 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| ASTM A36 | ≤0.22 | 0.50~0.90 | ≤0.40 | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | ≥250 | 400~500 | ASTM A36/A36M-03a |

| ASTM A105 | ≤0.35 | 0.6-1.05 | ≤0.35 | ≤0.050 | ≤0.040 | ≤0.20 | ≤0.20 | ≤0.30 | ≥310 | 485~620 | ASTM A105/A105M |

| SAE1013 | 0.11~0.16 | 0.50~0.80 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | ASTM A568/A568M-91a |

| SAE1015 | 0.13~0.18 | 0.30~0.60 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| SAE1017 | 0.15~0.20 | 0.30~0.60 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| SAE1018 | 0.15~0.20 | 0.60~0.90 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| SAE1020 | 0.18~0.23 | 0.30~0.60 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| S235JR | 0.15~0.20 | ≤1.4 | _ | ≤0.035 | ≤0.035 | ≤0.20 | _ | _ | ≥235 | 400~510 | EN10025 |

| S275JR | ≤0.22 | ≤1.4 | _ | ≤0.035 | ≤0.035 | ≤0.20 | _ | _ | ≥275 | 490~610 | |

| ST37-2 | 0.17~0.20 | ≤1.4 | _ | ≤0.045 | ≤0.045 | ≤0.20 | _ | _ | ≥235 |

| Diameter (mm) | Theoretical Weight (kg/m) | Diameter (mm) | Theoretical Weight (kg/m) |

| 5.5 | 0.186 | 13 | 1.04 |

| 6 | 0.222 | 14 | 1.21 |

| 6.5 | 0.26 | 15 | 1.39 |

| 7 | 0.302 | 16 | 1.58 |

| 8 | 0.395 | 17 | 1.78 |

| 9 | 0.499 | 18 | 2 |

| 10 | 0.617 | 19 | 2.23 |

| * 11 | 0.746 | 20 | 2.47 |

| 12 | 0.888 | 21 | 2.72 |

| 22 | 2.98 | 63 | 24.5 |

| * 23 | 3.26 | * 65 | 26 |

| 24 | 3.55 | * 68 | 28.5 |

| 25 | 3.85 | 70 | 30.2 |

| 26 | 4.17 | 75 | 34.7 |

| * 27 | 4.49 | 80 | 39.5 |

| 28 | 4.83 | 85 | 44.5 |

| * 29 | 5.18 | 90 | 49.9 |

| 30 | 5.55 | 95 | 55.6 |

| * 31 | 5.92 | 100 | 61.7 |

| 32 | 6.31 | 105 | 68 |

| * 33 | 6.71 | 110 | 74.6 |

| 34 | 7.13 | 115 | 81.5 |

| * 35 | 7.55 | 120 | 88.8 |

| 36 | 7.99 | 125 | 96.3 |

| 38 | 8.9 | 130 | 104 |

| 40 | 9.86 | 140 | 121 |

| 42 | 10.9 | 150 | 139 |

| 45 | 12.5 | 160 | 158 |

| 48 | 14.2 | 170 | 178 |

| 50 | 15.4 | 180 | 200 |

| 53 | 17.3 | 190 | 223 |

| * 55 | 18.6 | 200 | 247 |

| 56 | 19.3 | 220 | 298 |

| * 58 | 20.7 | 250 | 385 |

| 60 | 22.2 |

Standards and Classifications

| Products | Round Steel bar |

| Dia | 5.5mm~650mm |

| Length | 3m,6m,9m,12m |

| Standard | ASTM A 615 Gr 40/60,BSS4449 Gr460B,500B etc |

| Material | 3Cr2Mo/1.2311/1.2312/P20/1.2738/718H/P20+Ni/1.2316/1.2083/4Cr13 /sus420j2/420/S136/NAK80H13/1.2344/SKD61/5CrNiMo/SKT4/1.2714 Cr12/D3/1.2080/Cr12MoV/D2/1.2379/SKD11/9CrWMn/O1/1.2510/SKS3 /DC53 40Cr/5140/35CrMo/42CrMo/4140/1.7225 C45/C50/1045/1050/S50C/S45C/T10/T8 M2/1.338/SKH51 |

| Surface | ASTM,AISI,JIS,GB, DIN,EN |

| Technique | Hot rolled / cold rolled |

| Surface | Black Finish ,Oiled,Shot Blasted,Spray Paint,Coated,Galvanized, |

| Or as Your Request | |

| Package | In bundle, no other package or wrapped with waterproof, or as customers’ requirement |

| Payment Term | T/T, L/C at sight,West Union,Paypal |

| Price Term | FOB,CRF,CIF,EXW all acceptable |

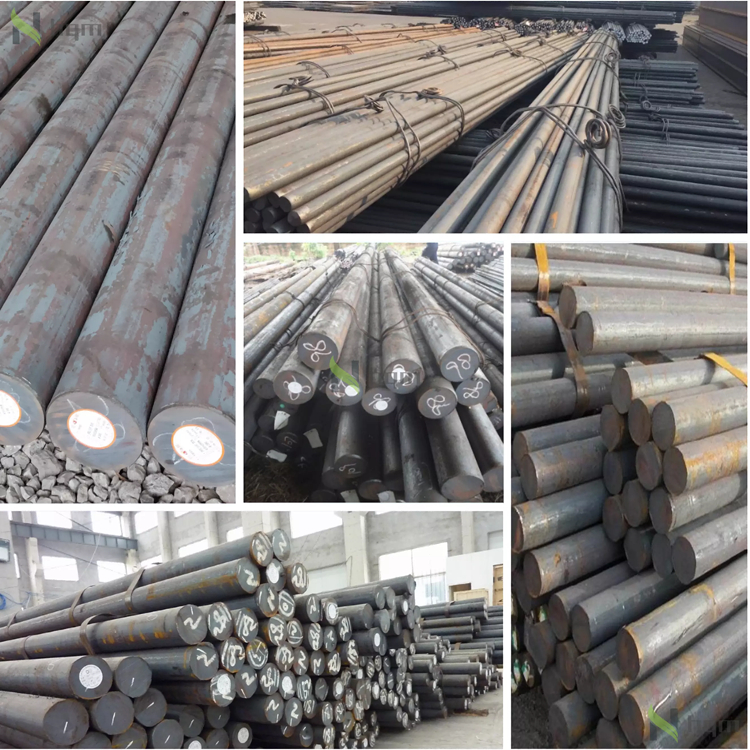

Product Display

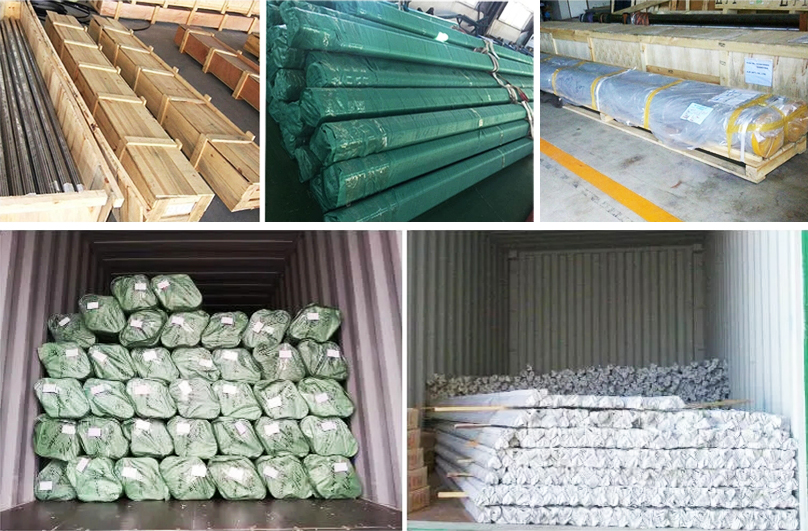

Packing & Delivery

Shipping By Sea

1. Standard packaging

2. Packaging according to customer requirements

Reviews

There are no reviews yet.