42CrMo Steel Round Bar

42CrMo Steel Round Bar is an ultra-high strength steel with high strength and toughness, good hardenability, no obvious temper brittleness, high fatigue limit and multiple impact resistance after quenching and tempering, and good low-temperature impact toughness. 42CrMo Round Steel Bar is suitable for manufacturing large and medium-sized plastic molds that require certain strength and toughness. Corresponding to AISI 4140 Steel Bar, 4142 Round Steel Bar, DIN 42CrMo4 Steel Bar and JIS SCM440 Steel Rod. If you want to buy or want to know the price, please feel free to leave a message.

Description

Product Description

42CrMo Steel Round Bar is an ultra-high strength steel with high strength and toughness, good hardenability, no obvious temper brittleness, high fatigue limit and multiple impact resistance after quenching and tempering, and good low-temperature impact toughness. 42CrMo Round Steel Bar is suitable for manufacturing large and medium-sized plastic molds that require certain strength and toughness. Corresponding to AISI 4140 Steel Bar, 4142 Round Steel Bar, DIN 42CrMo4 Steel Bar and JIS SCM440 Steel Rod. If you want to buy or want to know the price, please feel free to leave a message.

42CrMo Steel Round Bar is a low-alloy high-strength structural steel, which is characterized by high strength, good toughness, high hardenability, strong corrosion resistance, etc. Among them, the most notable characteristics are its high strength and toughness. At room temperature, the tensile strength of 42CrMo Steel Round Bar can be as high as 1930MPa, the yield point is 1270MPa, the elongation is 12%, and the section shrinkage is 40%. This high strength and toughness make 42CrMo Steel Round Bar an ideal material for manufacturing heavy machinery parts that bear heavy loads, high strength and high wear resistance.

Due to its excellent mechanical properties and process properties, 42CrMo Steel Round Bar is widely used in various engineering fields.

Standards

| Brand | Carbon Steel |

| Q195、Q215A、Q215B、Q235A、 | 1.5~ 25.4 ×780~2100× 2000 ~12000 |

| Q235B、Q235C、Q235D | |

| SS330、SS400 | 1.5~25.4 ×780~2100× 2000 ~ 12000 |

| S235JR+AR、S235J0+AR、S275JR+AR、S275J0+AR | |

| SPHC、SPHD | 1.5~14.0×780~2100× 2000 ~ 12000 |

| SPHE | 1.5 ~ 6.0 ×780 ~2100× 2000 ~ 12000 |

| DD11、DD12、DD13 | 1.5 ~ 8.0 ×780 ~2100× 2000 ~ 12000 |

| HCP |

| Brand | Appropriate standard |

| Q195、Q215A ~ Q235D | GB/T 709 |

| SS330、SS400 | JIS G 3193 |

| S235JR+AR、S235J0+AR | EN 10029 |

| S275JR+AR、S275J0+AR | |

| SPHC、SPHD、SPHE | JIS G3193 |

| DD11、DD12、DD13 | EN 10051 |

| HCP | WJX(RZ)571 |

| S45C | 0.42~0.48 | 0.60~0.90 | 0.15~0.35 | ≤0.03 | ≤0.03 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | JIS G4051-2005 |

| S20C | 0.18~0.23 | 0.30~0.60 | 0.15~0.35 | ≤0.03 | ≤0.035 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| ASTM A36 | ≤0.22 | 0.50~0.90 | ≤0.40 | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | ≥250 | 400~500 | ASTM A36/A36M-03a |

| ASTM A105 | ≤0.35 | 0.6-1.05 | ≤0.35 | ≤0.050 | ≤0.040 | ≤0.20 | ≤0.20 | ≤0.30 | ≥310 | 485~620 | ASTM A105/A105M |

| SAE1013 | 0.11~0.16 | 0.50~0.80 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | ASTM A568/A568M-91a |

| SAE1015 | 0.13~0.18 | 0.30~0.60 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| SAE1017 | 0.15~0.20 | 0.30~0.60 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| SAE1018 | 0.15~0.20 | 0.60~0.90 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| SAE1020 | 0.18~0.23 | 0.30~0.60 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| S235JR | 0.15~0.20 | ≤1.4 | _ | ≤0.035 | ≤0.035 | ≤0.20 | _ | _ | ≥235 | 400~510 | EN10025 |

| S275JR | ≤0.22 | ≤1.4 | _ | ≤0.035 | ≤0.035 | ≤0.20 | _ | _ | ≥275 | 490~610 | |

| ST37-2 | 0.17~0.20 | ≤1.4 | _ | ≤0.045 | ≤0.045 | ≤0.20 | _ | _ | ≥235 |

| Diameter (mm) | Theoretical Weight (kg/m) | Diameter (mm) | Theoretical Weight (kg/m) |

| 5.5 | 0.186 | 13 | 1.04 |

| 6 | 0.222 | 14 | 1.21 |

| 6.5 | 0.26 | 15 | 1.39 |

| 7 | 0.302 | 16 | 1.58 |

| 8 | 0.395 | 17 | 1.78 |

| 9 | 0.499 | 18 | 2 |

| 10 | 0.617 | 19 | 2.23 |

| * 11 | 0.746 | 20 | 2.47 |

| 12 | 0.888 | 21 | 2.72 |

| 22 | 2.98 | 63 | 24.5 |

| * 23 | 3.26 | * 65 | 26 |

| 24 | 3.55 | * 68 | 28.5 |

| 25 | 3.85 | 70 | 30.2 |

| 26 | 4.17 | 75 | 34.7 |

| * 27 | 4.49 | 80 | 39.5 |

| 28 | 4.83 | 85 | 44.5 |

| * 29 | 5.18 | 90 | 49.9 |

| 30 | 5.55 | 95 | 55.6 |

| * 31 | 5.92 | 100 | 61.7 |

| 32 | 6.31 | 105 | 68 |

| * 33 | 6.71 | 110 | 74.6 |

| 34 | 7.13 | 115 | 81.5 |

| * 35 | 7.55 | 120 | 88.8 |

| 36 | 7.99 | 125 | 96.3 |

| 38 | 8.9 | 130 | 104 |

| 40 | 9.86 | 140 | 121 |

| 42 | 10.9 | 150 | 139 |

| 45 | 12.5 | 160 | 158 |

| 48 | 14.2 | 170 | 178 |

| 50 | 15.4 | 180 | 200 |

| 53 | 17.3 | 190 | 223 |

| * 55 | 18.6 | 200 | 247 |

| 56 | 19.3 | 220 | 298 |

| * 58 | 20.7 | 250 | 385 |

| 60 | 22.2 |

Standards and Classifications

| Products | Round Steel bar |

| Dia | 5.5mm~650mm |

| Length | 3m,6m,9m,12m |

| Standard | ASTM A 615 Gr 40/60,BSS4449 Gr460B,500B etc |

| Material | 3Cr2Mo/1.2311/1.2312/P20/1.2738/718H/P20+Ni/1.2316/1.2083/4Cr13 /sus420j2/420/S136/NAK80H13/1.2344/SKD61/5CrNiMo/SKT4/1.2714 Cr12/D3/1.2080/Cr12MoV/D2/1.2379/SKD11/9CrWMn/O1/1.2510/SKS3 /DC53 40Cr/5140/35CrMo/42CrMo/4140/1.7225 C45/C50/1045/1050/S50C/S45C/T10/T8 M2/1.338/SKH51 |

| Surface | ASTM,AISI,JIS,GB, DIN,EN |

| Technique | Hot rolled / cold rolled |

| Surface | Black Finish ,Oiled,Shot Blasted,Spray Paint,Coated,Galvanized, |

| Or as Your Request | |

| Package | In bundle, no other package or wrapped with waterproof, or as customers’ requirement |

| Payment Term | T/T, L/C at sight,West Union,Paypal |

| Price Term | FOB,CRF,CIF,EXW all acceptable |

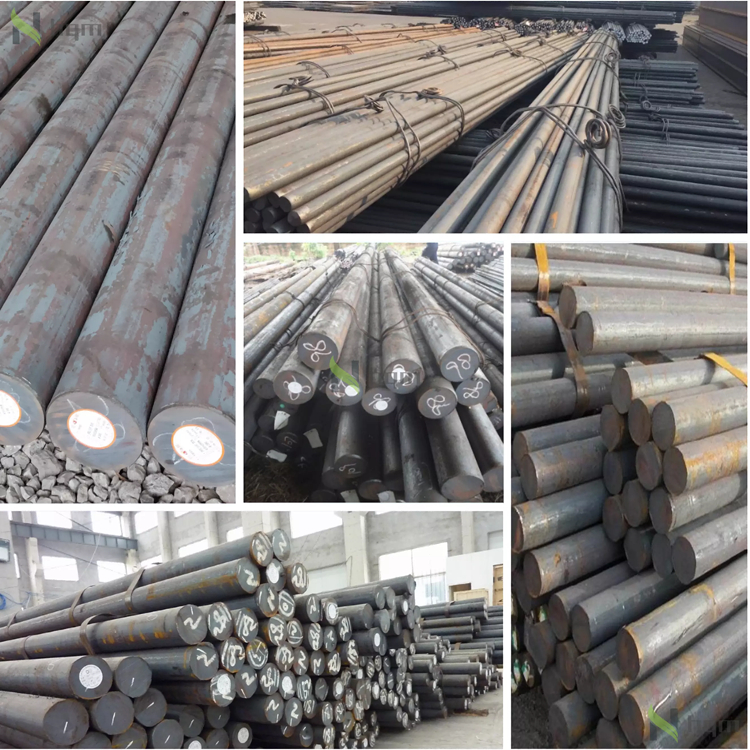

Product Display

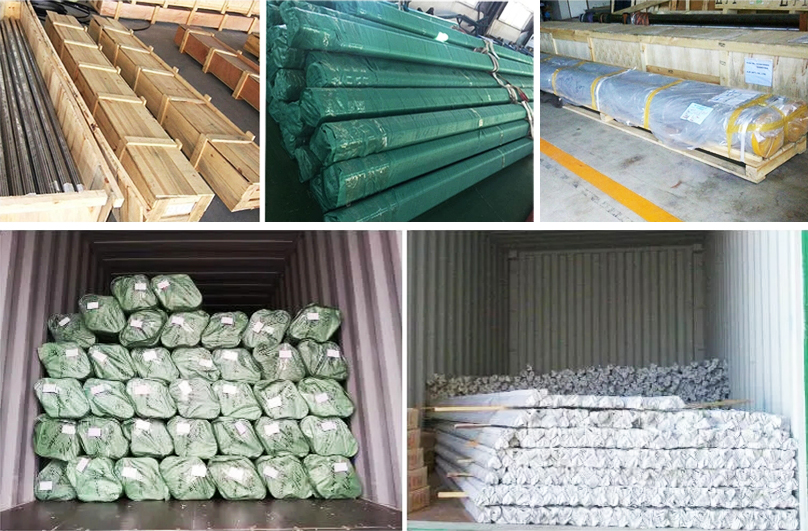

Packing & Delivery

Shipping By Sea

1. Standard packaging

2. Packaging according to customer requirements

Reviews

There are no reviews yet.