Welded Steel Pipe

Our company has advanced technology and can produce and supply various welded steel pipes, such as longitudinal submerged arc welded steel pipes, spiral submerged arc welded steel pipes, ERW steel pipes, etc. We are dedicated to providing you with the best quality products and best services.

Steel Grade:

10#, 20#, 45#, Q235, Q345, Q195, Q215, Q345C, Q345A, Q235A,Q235B, Q460, 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb, 16Mn, 20#, Q345, L245, L290, 40#, 60#, X42, X46, X70, X80

ASTM A53A/A53B, A178C, A106B, API5L, SS400

ST37, ST37-2, DIN 1629 ST35, ST45, DIN 17175 ST35.8, DIN 17175 19Mn5

16Mn, Q345B, T1, T2, T5, T9, T11, T12, T22, T91, T92, P1, P2, P5, P9, P11, P12, P22, P91, P92, 15CrMO, Cr5Mo, 10CrMo910, 12CrMo,

13CrMo44, 30CrMo, A333 GR.1, GR.3, GR.6, GR.7

Gr.B, X42, X46, X52, X60, X65, X70, X80, X100

Description

Our company has advanced technology and can produce and supply various welded steel pipes, such as longitudinal submerged arc welded steel pipes, spiral submerged arc welded steel pipes, ERW steel pipes, etc. We are dedicated to providing you with the best quality products and best services.

Product Description

Welded steel pipe refers to a steel pipe with seams on the surface that is made by bending and deforming a steel strip or steel plate into a round, square or other shape and then welding it. The blank used for welded steel pipe is a steel plate or strip.

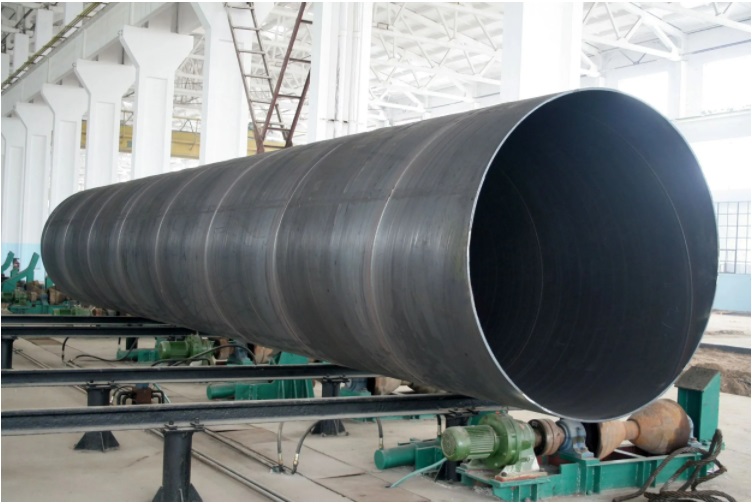

Welded steel pipes are divided into straight seam welded pipes and spiral welded pipes according to the weld form.

Classification by production method: Process classification – arc welded pipe, resistance welded pipe, (high frequency, low frequency) gas welded pipe, furnace welded pipe.

Smaller diameter welded pipes use straight seam welding, and large diameter welded pipes mostly use spiral welding; According to the end shape of steel pipes, they are divided into circular welded pipes and special-shaped (square, rectangular, etc.) welded pipes; According to different materials and uses, they are divided into mining fluids Welded steel pipes for transportation, galvanized welded steel pipes for low-pressure fluid transportation, electric welded steel pipes for belt conveyor rollers, etc.

Common materials for welded pipes include: Q235A, Q235C, Q235B, 16Mn, 20#, Q345, L245, L290, X42, X46, X60, X80, 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb, etc.

Standards

| Standard | Grade | Chemical Composition(max)% | Mechanical Properties(min) | |||||

| C | Si | Mn | P | S | Tensile Strength(Mpa) | Yield Strength(Mpa) | ||

| API 5CT | h40 | – | – | – | – | 0.030 | 417 | 417 |

| J55 | – | – | – | – | 0.030 | 517 | 517 | |

| K55 | – | – | – | – | 0.300 | 655 | 655 | |

| API 5L PSL1 | A | 0.22 | – | 0.90 | 0.030 | 0.030 | 335 | 335 |

| B | 0.26 | – | 1.20 | 0.030 | 0.030 | 415 | 415 | |

| X42 | 0.26 | – | 1.30 | 0.030 | 0.030 | 415 | 415 | |

| X46 | 0.26 | – | 1.40 | 0.030 | 0.030 | 435 | 435 | |

| X52 | 0.26 | – | 1.40 | 0.030 | 0.030 | 460 | 460 | |

| X56 | 0.26 | – | 1.40 | 0.030 | 0.030 | 490 | 490 | |

| X60 | 0.26 | – | 1.40 | 0.030 | 0.030 | 520 | 520 | |

| X65 | 0.26 | – | 1.45 | 0.030 | 0.030 | 535 | 535 | |

| X70 | 0.26 | – | 1.65 | 0.030 | 0.030 | 570 | 570 | |

| API 5L PSL2 | B | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 415 | 415 |

| X42 | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 415 | 415 | |

| X46 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 435 | 435 | |

| X52 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 460 | 460 | |

| X56 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 490 | 490 | |

| X60 | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 520 | 520 | |

| X65 | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 535 | 535 | |

| X70 | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 | 570 | 570 | |

| X80 | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 | 625 | 625 | |

| ASTM A53 | A | 0.25 | 0.10 | 0.95 | 0.050 | 0.045 | 330 | 330 |

| B | 0.30 | 0.10 | 1.20 | 0.050 | 0.045 | 415 | 415 | |

| ASTM A252 | 1 | – | – | – | 0.050 | – | 345 | 345 |

| 2 | – | – | – | 0.050 | – | 414 | 414 | |

| 3 | – | – | – | 0.050 | – | 455 | 455 | |

| EN10217-1 | P195TR1 | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P195TR2 | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 | |

| P235TR1 | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P235TR2 | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P265TR1 | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| P265TR2 | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10217-2 | P195GH | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P235GH | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 | |

| P265GH | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10217-5 | P235GH | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 |

| P265GH | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 | |

| EN10219-1 | S235JRH | 0.17 | – | 1.40 | 0.040 | 0.040 | 360 | 360 |

| S275JOH | 0.20 | – | 1.50 | 0.035 | 0.035 | 410 | 410 | |

| S275J2H | 0.20 | – | 1.50 | 0.030 | 0.030 | 410 | 410 | |

| S355JOH | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 470 | 470 | |

| S355J2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | 470 | 470 | |

| S355K2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | 470 | 470 | |

Standards and Classifications

| CLASSFICATION | STANDARD | MAIN PRODUCTS |

|---|---|---|

| Steel Pipe for Fluid Service | GB/T 14291 | Welded pipe for mine fluid sevice |

| GB/T 3091 | Welded pipe for low pressure fluid service | |

| SY/T 5037 | Spirally submerged arc welded steel pipe for pipelines for low pressure fluid service | |

| ASTM A53 | Black and hot-hipped galvanized welded and seamless steel pipe | |

| BS EN10217-2 | Welded steel tybes for pressure purposes – delivery technical conditions – part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties | |

| BS EN10217-5 | Welded steel tybes for pressure purposes – delivery technical conditions – part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties | |

| Steel Pipe for Ordinary Structure | GB/T 13793 | Longitudinally electric resistance welded steel pipe |

| SY/T 5040 | Spirally submerged arc welded steel pipe piles | |

| ASTM A252 | Welded and seamless steel pipe piles | |

| BS EN10219-1 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivert conditions | |

| BS EN10219-2 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part2: tolerances dimmsions and sectional properties | |

| Line Pipe | GB/T 9711.1 | Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) |

| GB/T 9711.2 | Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) | |

| PSL1/2 | Line pipe | |

| Casing | API 5CT/ ISO 11960 PSL1 | Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries |

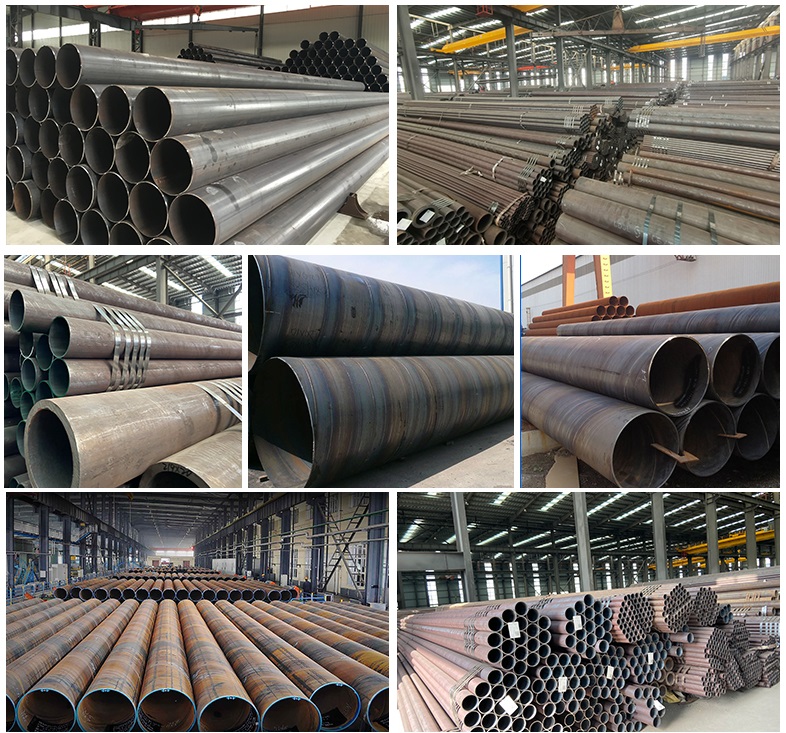

Product Display

Packing & Delivery

Shipping By Sea

1. Standard packaging

2. Packaging according to customer requirements

Reviews

There are no reviews yet.