Cr12 Too Steel Bar

Buy or purchase Cr12 Too Steel Bar, our factory can supply Cr12 Too Steel Bar of various diameters. If you want to know the price, please feel free to leave a message, we will give you the best service. Cr12 is an alloy tool steel with good hardenability and good wear resistance. It is mainly used for cold stamping dies and punches, cold cutting scissors, drill sleeves, gauges, wire drawing dies, stamping dies, thread rolling plates, drawing dies and thread rolling dies that bear small impact loads and require high wear resistance.

Description

Product Description

Buy or purchase Cr12 Too Steel Bar, our factory can supply Cr12 Too Steel Bar of various diameters. If you want to know the price, please feel free to leave a message, we will give you the best service. Cr12 is an alloy tool steel with good hardenability and good wear resistance. It is mainly used for cold stamping dies and punches, cold cutting scissors, drill sleeves, gauges, wire drawing dies, stamping dies, thread rolling plates, drawing dies and thread rolling dies that bear small impact loads and require high wear resistance.

The specific uses of Cr12 Too Steel Bar are as follows:

1. Mold manufacturing: Cr12 Steel Bar is often used to manufacture various cold stamping dies, cold heading dies, cold extrusion dies, drawing dies, etc. These dies need to withstand high pressure and friction during the manufacturing process. The high hardness and wear resistance of Cr12 Too Steel Rod make it an ideal choice.

2. Tool manufacturing: Cr12 Too Steel Bars are also used to manufacture cutting tools, measuring tools and cutting tools, etc. For example, cold cutting scissors, drill sleeves, wire drawing dies, stamping dies, thread rolling plates, etc. are all common applications of Cr12 Steel Bar.

3. Wear-resistant parts: Since Cr12 Too Steel Bars has good wear resistance, it is also used to manufacture parts that need to withstand greater friction and wear, such as bearings, gears, etc.

Standards

| Brand | Carbon Steel |

| Q195、Q215A、Q215B、Q235A、 | 1.5~ 25.4 ×780~2100× 2000 ~12000 |

| Q235B、Q235C、Q235D | |

| SS330、SS400 | 1.5~25.4 ×780~2100× 2000 ~ 12000 |

| S235JR+AR、S235J0+AR、S275JR+AR、S275J0+AR | |

| SPHC、SPHD | 1.5~14.0×780~2100× 2000 ~ 12000 |

| SPHE | 1.5 ~ 6.0 ×780 ~2100× 2000 ~ 12000 |

| DD11、DD12、DD13 | 1.5 ~ 8.0 ×780 ~2100× 2000 ~ 12000 |

| HCP |

| Brand | Appropriate standard |

| Q195、Q215A ~ Q235D | GB/T 709 |

| SS330、SS400 | JIS G 3193 |

| S235JR+AR、S235J0+AR | EN 10029 |

| S275JR+AR、S275J0+AR | |

| SPHC、SPHD、SPHE | JIS G3193 |

| DD11、DD12、DD13 | EN 10051 |

| HCP | WJX(RZ)571 |

| S45C | 0.42~0.48 | 0.60~0.90 | 0.15~0.35 | ≤0.03 | ≤0.03 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | JIS G4051-2005 |

| S20C | 0.18~0.23 | 0.30~0.60 | 0.15~0.35 | ≤0.03 | ≤0.035 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| ASTM A36 | ≤0.22 | 0.50~0.90 | ≤0.40 | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | ≥250 | 400~500 | ASTM A36/A36M-03a |

| ASTM A105 | ≤0.35 | 0.6-1.05 | ≤0.35 | ≤0.050 | ≤0.040 | ≤0.20 | ≤0.20 | ≤0.30 | ≥310 | 485~620 | ASTM A105/A105M |

| SAE1013 | 0.11~0.16 | 0.50~0.80 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | ASTM A568/A568M-91a |

| SAE1015 | 0.13~0.18 | 0.30~0.60 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| SAE1017 | 0.15~0.20 | 0.30~0.60 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| SAE1018 | 0.15~0.20 | 0.60~0.90 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| SAE1020 | 0.18~0.23 | 0.30~0.60 | _ | ≤0.040 | ≤0.050 | ≤0.20 | ≤0.20 | ≤0.30 | _ | _ | |

| S235JR | 0.15~0.20 | ≤1.4 | _ | ≤0.035 | ≤0.035 | ≤0.20 | _ | _ | ≥235 | 400~510 | EN10025 |

| S275JR | ≤0.22 | ≤1.4 | _ | ≤0.035 | ≤0.035 | ≤0.20 | _ | _ | ≥275 | 490~610 | |

| ST37-2 | 0.17~0.20 | ≤1.4 | _ | ≤0.045 | ≤0.045 | ≤0.20 | _ | _ | ≥235 |

| Diameter (mm) | Theoretical Weight (kg/m) | Diameter (mm) | Theoretical Weight (kg/m) |

| 5.5 | 0.186 | 13 | 1.04 |

| 6 | 0.222 | 14 | 1.21 |

| 6.5 | 0.26 | 15 | 1.39 |

| 7 | 0.302 | 16 | 1.58 |

| 8 | 0.395 | 17 | 1.78 |

| 9 | 0.499 | 18 | 2 |

| 10 | 0.617 | 19 | 2.23 |

| * 11 | 0.746 | 20 | 2.47 |

| 12 | 0.888 | 21 | 2.72 |

| 22 | 2.98 | 63 | 24.5 |

| * 23 | 3.26 | * 65 | 26 |

| 24 | 3.55 | * 68 | 28.5 |

| 25 | 3.85 | 70 | 30.2 |

| 26 | 4.17 | 75 | 34.7 |

| * 27 | 4.49 | 80 | 39.5 |

| 28 | 4.83 | 85 | 44.5 |

| * 29 | 5.18 | 90 | 49.9 |

| 30 | 5.55 | 95 | 55.6 |

| * 31 | 5.92 | 100 | 61.7 |

| 32 | 6.31 | 105 | 68 |

| * 33 | 6.71 | 110 | 74.6 |

| 34 | 7.13 | 115 | 81.5 |

| * 35 | 7.55 | 120 | 88.8 |

| 36 | 7.99 | 125 | 96.3 |

| 38 | 8.9 | 130 | 104 |

| 40 | 9.86 | 140 | 121 |

| 42 | 10.9 | 150 | 139 |

| 45 | 12.5 | 160 | 158 |

| 48 | 14.2 | 170 | 178 |

| 50 | 15.4 | 180 | 200 |

| 53 | 17.3 | 190 | 223 |

| * 55 | 18.6 | 200 | 247 |

| 56 | 19.3 | 220 | 298 |

| * 58 | 20.7 | 250 | 385 |

| 60 | 22.2 |

Standards and Classifications

| Products | Round Steel bar |

| Dia | 5.5mm~650mm |

| Length | 3m,6m,9m,12m |

| Standard | ASTM A 615 Gr 40/60,BSS4449 Gr460B,500B etc |

| Material | 3Cr2Mo/1.2311/1.2312/P20/1.2738/718H/P20+Ni/1.2316/1.2083/4Cr13 /sus420j2/420/S136/NAK80H13/1.2344/SKD61/5CrNiMo/SKT4/1.2714 Cr12/D3/1.2080/Cr12MoV/D2/1.2379/SKD11/9CrWMn/O1/1.2510/SKS3 /DC53 40Cr/5140/35CrMo/42CrMo/4140/1.7225 C45/C50/1045/1050/S50C/S45C/T10/T8 M2/1.338/SKH51 |

| Surface | ASTM,AISI,JIS,GB, DIN,EN |

| Technique | Hot rolled / cold rolled |

| Surface | Black Finish ,Oiled,Shot Blasted,Spray Paint,Coated,Galvanized, |

| Or as Your Request | |

| Package | In bundle, no other package or wrapped with waterproof, or as customers’ requirement |

| Payment Term | T/T, L/C at sight,West Union,Paypal |

| Price Term | FOB,CRF,CIF,EXW all acceptable |

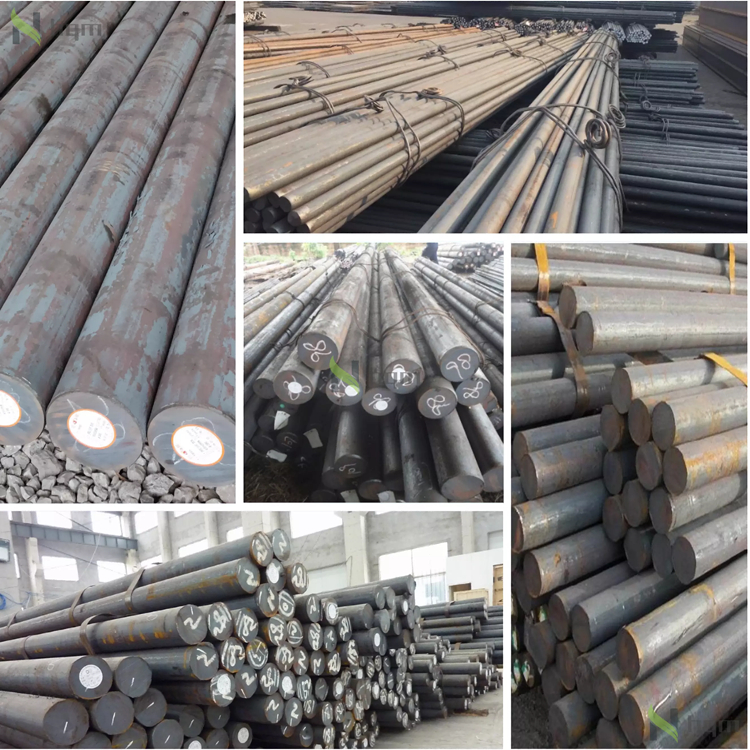

Product Display

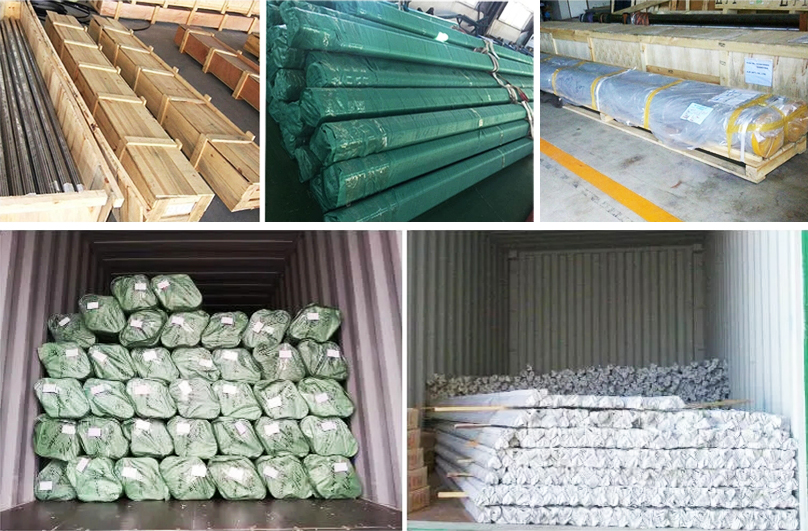

Packing & Delivery

Shipping By Sea

1. Standard packaging

2. Packaging according to customer requirements

Reviews

There are no reviews yet.