Stainless Steel Rod

Stainless Steel Rod is a common stainless steel product, usually used to make mechanical parts, hardware accessories, bicycle parts, locks, etc. There are many kinds of materials for Stainless Steel Rod, among which the more common ones are as follows: 304 Stainless Steel Rod, 316 Stainless Steel Rod, 430 Stainless Steel Rod, 310S Stainless Steel Rod, 904L Stainless Steel Rod, etc. Each material of Stainless Steel Rod has its own unique characteristics and uses.

Description

We have all kinds of stainless steel products, such as stainless steel rod, stainless steel tube, stainless steel plate, stainless steel coil and so on. If you need high-quality stainless steel suppliers and manufacturers in China, please feel free to consult and purchase, we will provide you with the most favorable prices and services.

Product Description

Stainless Steel Rod is a common stainless steel product, usually used to manufacture mechanical parts, hardware accessories, bicycle parts, locks, etc.

Stainless Steel Rod has many materials, among which the more common ones are as follows:

304 Stainless Steel Rod: It is a commonly used stainless steel material with good corrosion resistance, weldability and mechanical properties. It is suitable for manufacturing chemical, textile, food processing equipment, etc.

316 Stainless Steel Rod: Compared with 304 stainless steel rod, 316 stainless steel rod has higher corrosion resistance and high temperature resistance, and is suitable for manufacturing marine equipment, chemical equipment, etc.

201 Stainless Steel Rod: Compared with 304 stainless steel rod, 201 stainless steel rod has a lower nickel content, but has higher strength and good corrosion resistance, and is suitable for manufacturing furniture, building materials, etc.

430 Stainless Steel Rod: It is a ferritic stainless steel material with good heat resistance, corrosion resistance and mechanical properties. It is suitable for manufacturing automobile exhaust pipes, kitchen utensils, etc.

In addition to the common materials mentioned above, there are many other types of Stainless Steel Rod, such as 310S Stainless Steel Rod, 904L Stainless Steel Rod, etc. Each material of Stainless Steel Rod has its unique characteristics and uses, and the appropriate material should be selected according to specific needs.

Standards

GB/T14975-2002,GB/T14976-2002 ,GB/T13296-91,ASTM A484/A484M,ASTM A213/213A ,ASTM A269/269M

|

GB/T20878

|

JIS

|

ASTM

|

KS

|

BSEN

|

AS

|

CNS

|

t/m3 |

|

12Cr13

|

SUS403

|

403

|

STS403

|

—

|

403

|

403

|

7.75

|

|

20Cr13

|

SUS420J1

|

420

|

STS420J1

|

1.4021

|

420

|

420J1

|

7.75

|

|

30Cr13

|

SUS420J2

|

—

|

STS420J2

|

1.4028

|

420J2

|

420J2

|

7.75

|

|

10Cr17

|

SUS430

|

430

|

STS430

|

1.4016

|

430

|

430

|

7.70

|

|

68Cr17

|

SUS440A

|

440A

|

STS440A

|

—

|

440A

|

440A

|

7.70

|

|

06Cr19Ni10

|

SUS304

|

304

|

STS304

|

1.4301

|

304

|

304

|

7.93

|

|

022Cr19Ni10

|

SUS304L

|

304L

|

STS304L

|

1.4306

|

304L

|

304L

|

7.93

|

|

06Cr17Ni12Mo2

|

SUS316

|

316

|

STS316

|

1.4401

|

316

|

316

|

7.98

|

|

022Cr17Ni12Mo2

|

SUS316L

|

316L

|

STS316L

|

1.4404

|

316L

|

316L

|

7.98

|

|

06Cr18Ni11Ti

|

SUS321

|

321

|

STS321

|

1.4541

|

321

|

321

|

7.93

|

|

06Cr18Ni11Nb

|

SUS347

|

347

|

STS347

|

1.455

|

347

|

347

|

7.98

|

Standards and Classifications

| Steel Grade | GB China | JIS Japan | ASTM America | Din German | |||

| Steel Grade | Steel Grade | Steel Standard | Steel Grade | Steel Grade | Material | Steel Standard | |

| Stainless Sour Resistant Steel Pipe/Tube | (1Gr13Steel Pipe/Tube) | SUS410 TP | G3463 | ASTM A268 TP410 | X10Cr13 | 1.4006 | DIN17440 |

| (2Cr13Steel Pipe/Tube) | ASTM (SISI 420) | X20Cr13 | 1.4021 | DIN17440 | |||

| (1Cr17Steel Pipe/Tube) | SUS430 TB | G3463 | ASTM A268 TP430/TP429 | X8Cr17 | 1.4016 | DIN17440 | |

| 0Cr18Ni9Stainless Steel Pipe/Tube | SUS304 TP/TB | G3459 G3463 | ASTM A312、A376、TP304 A213、A249、A268 TP304 | X5CrNi189 | 1.4301 | DIN17440 | |

| (1Cr18Ni9 Stainless Steel Pipe/Tube) |

X5CrNi189 | 1.4301 | DIN17440 | ||||

| 0Cr18Ni10Ti Stainless Steel Pipe/Tube 1Cr18Ni9Ti Stainless Steel Pipe/Tube |

SUS321 TP/TB | G3459 G3463 | ASTM A312、A376 TP321 A213、A249、A266 TP321 | X10CrNiTi189 | 1.4541 | DIN17440 | |

| 0Cr18Ni13Mo2TiStainless Steel Pipe/Tube | SUS316 TP/TB | G3459 G3463 | ASTM A312、A376 TP316 A213、A249、A266 TP316 | ||||

| 0Cr18Ni13Mo3TiStainless Steel Pipe/Tube | SUS317 TP/TB | G3459 G3463 | ASTM A312、A376 TP316 A213、A249、A268 TP317 | ||||

| 00Cr18Ni10 Stainless Steel Pipe/Tube |

SUS304L TP/TB | G3459 G3463 | ASTM A312、A376 TP34L A213、A249、A268 TP304L | X2CrNi189 | 1.4306 | DIN17440 | |

| 00Cr17Ni13Mo2 Stainless Steel Pipe/Tube |

SUS316L TP/TB | G3459 G3463 | ASTM A312、A376 TP316L A213、A249、A268 TP316L | X2CrNi810 | 1.4404 | DIN17440 | |

| 00Cr17Ni13Mo3 Stainless Steel Pipe/Tube |

SUS317L TP/TB | G3459 G3463 | A312、A376、 TP317L A213、A249、A268 TP317L | ||||

| Surface Finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

| STAINLESS STEEL CHEMICAL COMPONENT | ||||||||

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 | ≤0.75 | 5.5-7.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 16.0-18.0 | – |

| 202 | ≤0.15 | ≤1.0 | 7.5-10.0 | ≤0.06 | ≤0.03 | 4.-6.0 | 17.0-19.0 | – |

| 301 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 6.0-8.0 | 16.0-18.0 | – |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 8.0-10.0 | 17.0-19.0 | – |

| 304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 8.0-10.5 | 18.0-20.0 | |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-13.0 | 18.0-20.0 | |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 12.0-15.0 | 22.0-24.0 | |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-13.0 | 17.0-19.0 | – |

| 904L | ≤2.0 | ≤0.045 | ≤1.0 | ≤0.035 | – | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.80 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤0.03 | 0.19-0.22 | 0.24-0.26 | – |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | – | 11.5-13.5 | – |

| 430 | 0.12 | ≤0.75 | ≤1.0 | ≤0.040 | ≤0.03 | ≤0.60 | 16.0-18.0 | – |

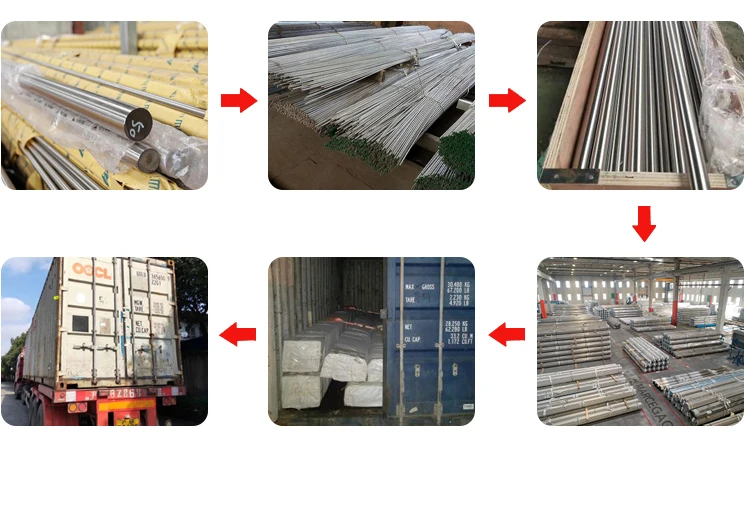

Packing & Delivery

Shipping By Sea

1. Standard packaging

2. Packaging according to customer requirements

Reviews

There are no reviews yet.