NM400 Abrasion Resistant Steel Plate

NM400 abrasion resistant steel plate is a high-strength wear-resistant steel plate. NM400 abrasion resistant steel plate has very high mechanical strength; its mechanical properties are 3 to 5 times that of ordinary low alloy steel plates; it can significantly improve the wear resistance of machinery-related parts; thus increasing the service life of machinery; reducing production costs. This product Surface hardness usually reaches 360~450HB.

Description

Buy our national standard abrasion resistant steel plate: mainly divided into NM360 abrasion resistant steel plate, NM400 steel plate, NM450 steel plate, NM500 steel plate and other models, produced by Wugang, Baosteel and other steel mills.

Domestic wear-resistant plates: widely used in mining machinery, coal mining machinery, environmental protection machinery, engineering machinery, cement machinery, metallurgical machinery, brick-making machinery and other product parts, such as excavators, loaders, bulldozer bucket plates, blade plates, side blade plates, crusher liners, blades, etc.

Product Description

NM400 abrasion resistant steel plate is a high-strength wear-resistant steel plate. NM400 abrasion resistant steel plate has very high mechanical strength; its mechanical properties are 3 to 5 times that of ordinary low alloy steel plates; it can significantly improve the wear resistance of machinery-related parts; thus increasing the service life of machinery; reducing production costs. This product Surface hardness usually reaches 360~450HB.

NM400 abrasion resistant steel plate is widely used in product parts such as engineering machinery, mining machinery, coal mining machinery, environmental protection machinery, and metallurgical machinery. Excavator, loader, bulldozer bucket plate, blade plate, side blade plate, blade. Crusher liners and blades.

NM400 wear-resistant steel plate conventional size: 8-80mm*2000-2500mm*8000-12000mm

Standards

| Grade | |||||

| Chemical Composition ( ≤ ) | NM300 | NM360 | NM400 | NM450 | NM500 |

| C | 0.23 | 0.25 | 0.3 | 0.35 | 0.38 |

| Si | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Mn | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| P | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 |

| S | 0.015 | 0.015 | 0.01 | 0.01 | 0.01 |

| Cr | 0.7 | 0.8 | 1 | 1.1 | 1.2 |

| Ni | 0.5 | 0.5 | 0.7 | 0.8 | 1 |

| Mo | 0.4 | 0.5 | 0.5 | 0.55 | 0.65 |

| Thickness (mm) | ≤80 | ≤80 | ≤80 | ≤80 | ≤70 |

| Tensile strength (MPa) | ≥1000 | ≥1100 | ≥1200 | ≥1250 | — |

| Elongation A (%) | ≥14 | ≥12 | ≥10 | ≥7 | — |

| Surface Brinell hardness (HBW) | 270-330 | 330-390 | 370-430 | 420-480 | ≥470 |

| Grade Comparison | |||||

| GB | NM300,NM360,NM400,NM450,NM500 | ||||

| SS | HARDNESS400, HARDNESS450, HARDNESS500, HARDNESS600 | ||||

| DIN | XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500 | ||||

| NBN | QUARD400, QUARD450, QUARD500 | ||||

| NF | FORA400, FORA500, Creusabro4800, Creusabro8000 | ||||

| JIS | JFE-EH360 , JFE – EH400 , JFE – EH500 , WEL-HARD400 , WELHARD500 | ||||

| SFS | RAEX400, RAEX450, RAEX500 | ||||

| Mechanical Properties | ||||||

| Material | Thickness(mm) | Strength of extension | Elongation | Impact energy(vertical) | BH(Brinell Hardness) | |

| ℃ | Akv/J | |||||

| NM300 | 6-80 | ≥1000 | ≥14 | -20 | ≥24 | 270-300 |

| NM360 | 6-80 | ≥1100 | ≥12 | -20 | ≥24 | 330-390 |

| NM400 | 6-80 | ≥1200 | ≥10 | -20 | ≥24 | 370-430 |

| NM450 | 6-80 | ≥1250 | ≥7 | -20 | ≥24 | 420-480 |

| NM500 | 6-70 | / | / | / | / | ≥470 |

| NM550 | 6-70 | / | / | / | / | ≥530 |

| HarDox450 | 5-50 | ≥1400 | 10 | -40 | ≥35 | 425~475 |

| HarDox500 | 5-50 | / | / | -40 | ≥30 | 450~540 |

| HarDox550 | 5-50 | / | / | -40 | ≥24 | 450~540 |

Standards and Classifications

| Standard | GB | ASTM | SSAB OXELOSUND | JIS |

| GRADE | NM360, NM400, NM450, NM500, NM550, NM600 | XAR400, XAR450, XAR500, XAR550 | HAR400, HAR450, HAR500, HAR550, HAR600 | NK-EH360, JFE-EH400, JFE-EH450, JFE-EH500 |

| Thickness | 6.0-200mm,etc | |||

| Width | 1500-4100mm,etc | |||

| Length | 2000-12000mm,etc | |||

| Standard | ASTM,AISI,JIS,GB, DIN,EN | |||

| Certification | ISO, SGS,BV | |||

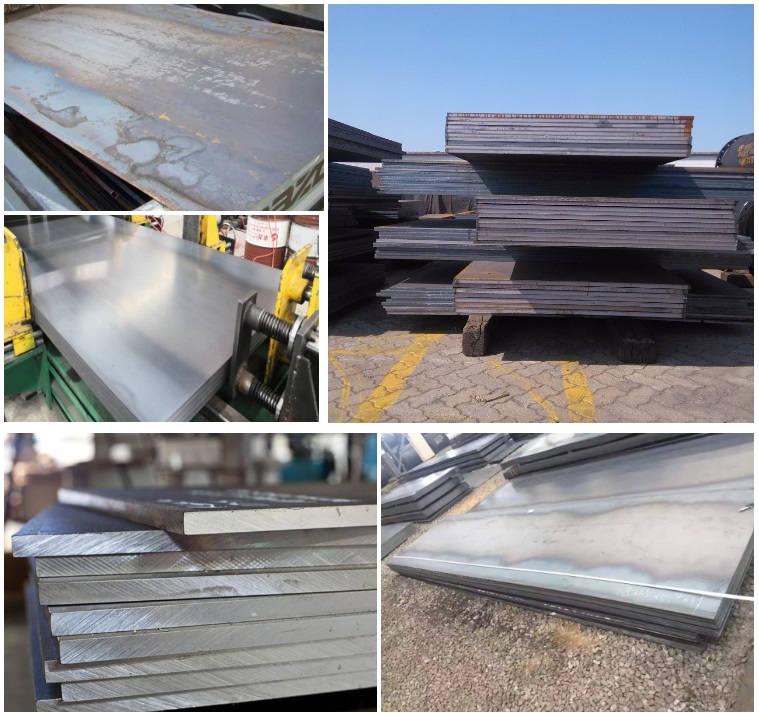

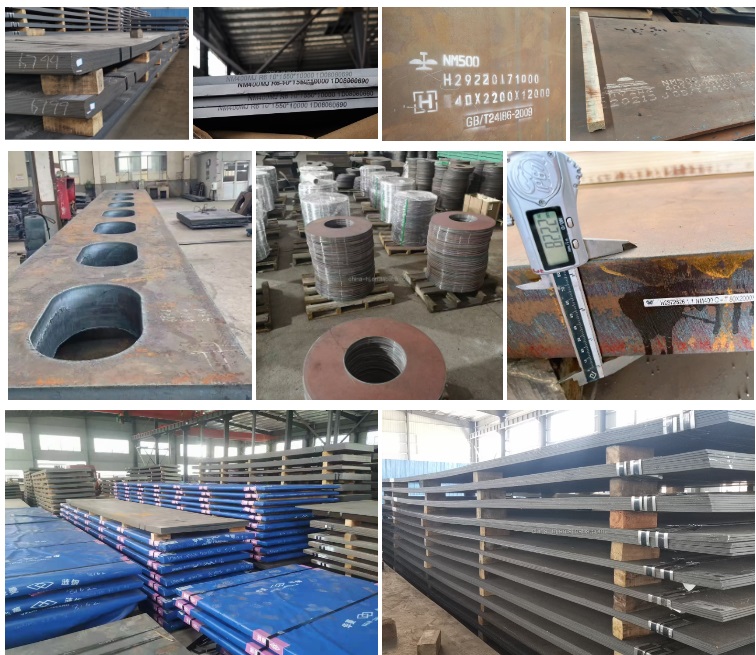

Product Display

Packing & Delivery

Shipping By Sea

1. Standard packaging

2. Packaging according to customer requirements

Reviews

There are no reviews yet.