Ni36 Alloy Steel Plate 4J36 Steel Sheet

Ni36 Alloy Steel Plate, also known as low expansion iron-nickel alloy, is a type of material with extremely low thermal expansion coefficient. Its application scenarios cover aerospace, precision instrument manufacturing, electronics industry and other fields. Ni36 alloy (or Invar 36) is favored by various industries due to its excellent stability and high temperature resistance. It can still maintain dimensional stability in occasions with drastic temperature changes.

Description

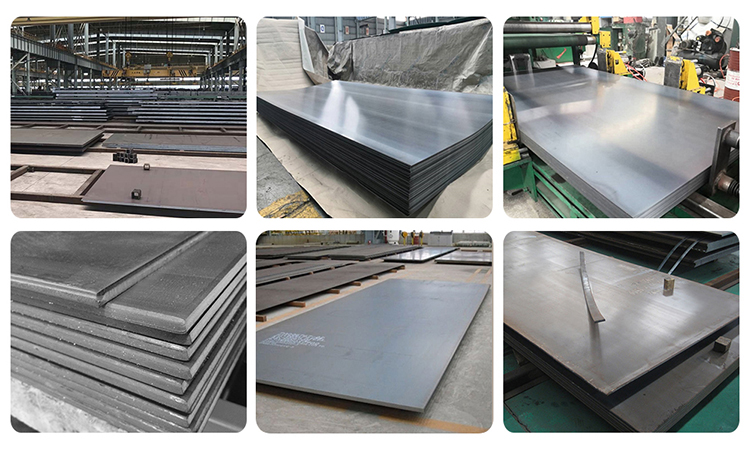

Alloy steel plate is a very important industrial material, and its application is more and more extensive. We can supply you with various specifications of alloy steel plates, structural steel plates, pressure vessel plates, wear-resistant steel plates, etc.

Product Description

Ni36 Alloy Steel Plate, also known as low expansion iron-nickel alloy, is a type of material with extremely low thermal expansion coefficient. Its application scenarios cover aerospace, precision instrument manufacturing, electronics industry and other fields. Ni36 alloy (or Invar 36) is favored by various industries due to its excellent stability and high temperature resistance. It can still maintain dimensional stability in occasions with drastic temperature changes.

The unique properties of Ni36 Alloy Steel Plate come from its precisely controlled chemical composition. Generally, the main components of Ni36 Alloy Steel Plate are nickel (about 36%) and iron, which have extremely low thermal expansion coefficient. In a wide temperature range of -250°C to 200°C, the expansion coefficient of Ni36 alloy is only 1.2×10^-6/K, which is much lower than that of general steel and other alloy materials. This property enables Ni36 alloy to maintain dimensional stability in an environment with large temperature differences, thereby greatly reducing the risk of structural failure due to thermal expansion.

Ni36 Alloy Steel Plate has good mechanical properties, such as high tensile strength, yield strength and impact toughness. For example, the tensile strength of Ni36 alloy at 20°C can usually reach 490MPa, and the hardness is about HB140-190. These characteristics allow it to be used for a long time in a high-stress environment, and it is also not unstable at extreme temperatures, which is particularly suitable for occasions requiring high precision and high reliability.

Due to the stability advantage of Ni36 Alloy Steel Plate, it is widely used in multiple industries with high precision requirements:

Aerospace: Equipment in the aerospace field usually operates in extreme temperatures. Ni36 Alloy Steel Plate can ensure that onboard electronic equipment, instruments and engine components will not have dimensional deviations when the temperature fluctuates, which is particularly important for navigation and measurement equipment.

Precision machinery and electronics industry: When manufacturing equipment such as laser systems, optical instruments and high-precision measuring tools, any slight dimensional changes will affect the measurement and operation accuracy. Using Ni36 Alloy Steel Plate as the housing and frame material of these devices can ensure that the impact of temperature changes on system accuracy is minimized.

Energy Industry: Ni36 Alloy Steel Sheet is also used in deep well drilling equipment and nuclear reactors, especially in extreme high temperature and pressure environments, the alloy can provide excellent stability and durability.

Other Special Fields: Ni36 Alloy Steel Plates also perform well in petrochemical equipment, low temperature storage equipment and other occasions requiring dimensional accuracy and heat resistance.

Standards

| Standard | Carbon Steel, HSLA High Strength Low Alloy Steel Grades | |||

| ASME SA36/ASTM A36 | A36 | |||

| ASME SA283/ASTM A283 | A283 Grade C | A283 Grade D | ||

| ASME SA387/ASTM A387 | A387 Grade 2 | A387 Grade 5 | A387 Grade 9 | A387 Grade 11 |

| A387 Grade 12 | A387 Grade 17 | A387 Grade 21 | A387 Grade 21L | |

| A387 Grade 22 | A387 Grade 22L | A387 Grade 91 | ||

| ASME SA572/ASTM A572 | A572 Grade 42 | A572 Grade 50 | A572 Grade 55 | A572 Grade 60 |

| A572 Grade 65 | ||||

| ASME SA573/ASTM A573 | A573 Grade 58 | A573 Grade 65 | A573 Grade 70 | |

| ASME SA633/ASTM A633 | A633 Grade A | A633 Grade C | A633 Grade D | A633 Grade E |

| ASME SA656/ASTM A656 | A656 Grade 50 | A656 Grade 60 | A656 Grade 70 | A656 Grade 80 |

| A656 Grade 100 | ||||

| EN10025-2 | S235JR | S235J0 | S235J2 | S275JR |

| S275J0 | S275J2 | S355JR | S355J0 | |

| S355J2 | S355K2 | S450J0 | ||

| EN10025-3 | S275N | S275NL | S355N | S355NL |

| S420N | S420NL | S460N | S460NL | |

| EN10025-4 | S275M | S275ML | S355M | S420ML |

| S355ML | S460M | S420M | S460ML | |

| EN10025-6 | S460Q | S460QL | S460QL1 | S500Q |

| S500QL | S500QL1 | S550Q | S550QL | |

| S550QL1 | S620Q | S620QL | S620QL1 | |

| S690Q | S690QL | S890Q | S690QL1 | |

| S890QL | S890QL1 | S960Q | S960QL | |

| JIS G3101 | SS330 | SS400 | SS490 | SS540 |

| JIS G3106 | SM400A | SM400B | SM400C | SM490A |

| SM490B | SM490C | SM490YA | SM490YB | |

| SM520B | SM520C | SM570 | ||

| JIS G4051 | S20C | S25C | S30C | S35C |

| S40C | S45C | S50C | S55C | |

| S60C | S65C | S70C | S75C | |

| DIN 17100 | St37-2 | USt37-2 | RSt37-2 | St37-3 |

| St52-3 | ||||

| DIN 17102 | StE255 | WStE255 | TStE255 | EStE255 |

| StE285 | WStE285 | TStE285 | EStE285 | |

| StE315 | WStE315 | TStE315 | EStE315 | |

| StE355 | WStE355 | TStE355 | EStE355 | |

| StE380 | WStE380 | TStE380 | EStE380 | |

| StE420 | WStE420 | TStE420 | EStE420 | |

| StE460 | WStE460 | TStE460 | EStE460 | |

| StE500 | WStE500 | TStE500 | EStE500 | |

| GB/T700 | Q195 | Q235A | Q235B | Q235C |

| Q235D | Q275 | |||

| GB/T1591 | Q355B | Q355C | Q355D | Q390B |

| Q390C | Q420B | Q420C | Q460C | |

| Q390N | Q420N | Q460N | Q390M | |

| Q420M | Q460M | Q550M | Q620M | |

| Q690M | ||||

| GB/T16270 | Q460C | Q460D | Q460E | Q460F |

| Q500C | Q500D | Q500E | Q500F | |

| Q550C | Q550D | Q550E | Q550F | |

| Q620C | Q620D | Q620E | Q620F | |

| Q690C | Q690D | Q690E | Q690F | |

| Q800C | Q800D | Q800E | Q800F | |

| Q890C | Q890D | Q890E | Q890F | |

| Q960C | Q960D | Q960E | Q960F | |

Standards and Classifications

| GB | 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 65, 70, Q195, Q215, Q235, Q255, Q275, Q295, Q345, 08F, 10F, 15F, 08, 08Al, 10, Q420, Q460, Q500, Q550, Q620, Q690, A32, D32, E32, F32, A36, D36, E36, F36, A40, D40, E40, F40, 20G, 22MnG, LT, XT1, XT2, HP245, HP265, HP295, HP325, HP345, HP365, 45Mn2, 27SiMn, 40B, 45B, 50B, 15Cr, 20Cr, 15CrMoG, 16MnG, 19MnG, 13MnNiCrMoNbG, 12Cr1MoVG, 16MnDR, 15MnNiDR, 09MnNiDR, 20R, 16MnR, 15MnNbR, 15MnVR, 15MnVNR, 18MnMoNbR, 13MnNiMoNbR, 15CrMoR, 07MnCrMoVR, 07MnNiMoVDR, 12MnNiVR, etc |

| ASTM | ASTM A414/A414M A/B/C/D/E/F/G, ASTM A515/A515M 415/450/485, ASTM A516/A516M 380/415/450/485, ASTM A204/A204M A/B/C, ASTM A537/A537M 1/2/3, ASTM A202/A202M A/B, ASTM A203/A203M A/B/D/E/F, ASTM A225/A225M C/D, ASTM A737/A737M B/C, ASTM A353/A353M, ASTM A387/A387M 2/12/11/12/22L/21/21L/5/17/9/91, ASTM A517/A517M A/B/C/E/F/H/J/M/P/Q/S/T, ASTM A533/A533M A/B/C/D, ASTM A542/A542M A/B/C/D/E, ASTM A543/A543M B/C, ASTM A782/A782M,ASTM A844/A844M, etc |

| JIS | SGV410, SGV450, SGV480, SPV235/315/355/410/450/490, SB410/450/480, SG255, SG295, SG325, SG365, SLA235A/235B/325A/325B/365/410, SB450M/480M, SQV3A/3B, SEV245/295/345, SL2N255, SL3N255/275/440, SL5N590, SL9N520/590, SCMV1/2/3/4 /5/6, SCMQ4E/4V/5V, SBV1A/1B/2/3, SQV1A/1B/2A/2B, SS330, SS400, SS490, SS540, SM400A/400B/400C/490A/490B/490C/490YA /490YB/520B/520C/570, SMA400AW/400AP/400BW/400BP/400CW/400CP/490AW/490AP/490BW/490BP/490CW/490CP/570W/570P, SPA-H, SPA-C,etc |

| DIN | P245NB, P265NB, P310NB, P355NB, X6CrNi1811, X3CrNiN1811, X8CrNiTi1810, X6CrNiMo1713, X3CrNiMoN1713, X8CrNiNb1613, X8CrNiMoNb1616, X8CrNiMoVNb1613, X5NiCrAlTi3120, X8NiCrAlTi3221, X5NiCrAlTi3120RK, P235GH, P265GH, P295GH, P355GH, 16Mo3, 13CrMo4-5, 10CrMo9-10, 11CrMo9-10, etc |

| EN | S185(1.0035), S235J0(1.0114), S235JR(1.0038), S235J2(1.0117), S275JR(1.0044), S275J0(1.0143), E295, S355J0(1.0553), E335(1.0060), S235J2W(1.8961), S355J2W(1.8965), P235GH, P265GH, P295GH, P355GH, 16Mo3, 13CrMo45(1.7335), 10CrMo9-10, 12Ni14, X12Ni5, X8Ni9, etc |

Product Display

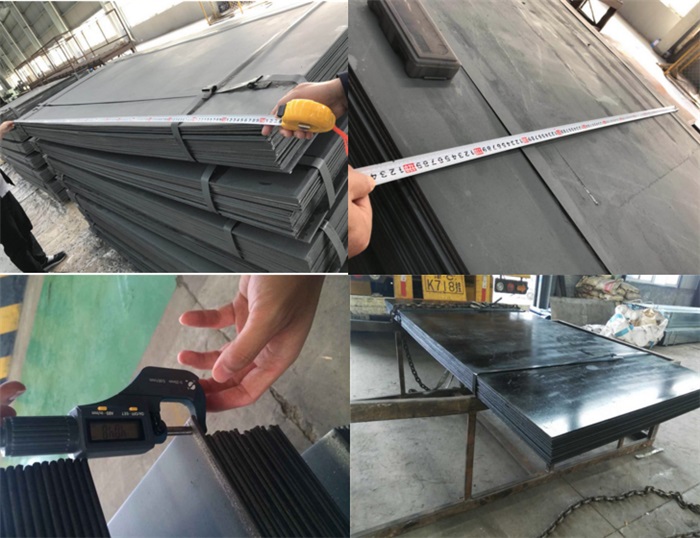

Packing & Delivery

Shipping By Sea

1. Standard packaging

2. Packaging according to customer requirements

Reviews

There are no reviews yet.