Wear Resistant Steel Plate

We can supply various specifications of wear-resistant steel plates, wear-resistant steel plates, NM steel plates, HB steel plates, Hardox steel plates, etc. It can be customized and has a large inventory. We sincerely invite you to cooperate.

Steel Grade:

Standards:

HARD 400, 450, 500, 550, 600, Ar360, 400, 450, NM400, 450, 500

Har-X400, Har-X450, Har-X500, Har-X600, SB-50, SB-45

XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500

QUARD400, QUARD450, QUARD500

FORA400, FORA500, Creusabro4800, Creusabro8000

RAEX400, RAEX450, RAEX500

JFE-EH360, JFE-EH400, JFE-EH500, WEL-HARD400, WEL-HARD500

Description

The characteristics of wear-resistant steel plate include high yield strength and tensile strength, so that it can provide effective protection in the occasions or parts that require wear protection. We can supply various specifications of wear-resistant steel plates, NM steel plates, HB steel plates, Hardox steel plates, carbon steel plate,etc. It can be customized and has a large inventory.

Product Description

Wear-resistant steel plates refer to special plate products specially used under large-area wear conditions. Commonly used wear-resistant steel plates are plate products that form a certain thickness of alloy wear-resistant layer with high hardness and excellent wear resistance on the surface of ordinary low carbon steel plates or low alloy steel plates with good toughness, as well as the plasticity obtained through surfacing. In addition, there are cast wear-resistant steel plates and alloy quenched wear-resistant steel plates.

Wear-resistant steel plates are composed of low-carbon steel plates and alloy wear-resistant layers. The alloy wear-resistant layer is generally 1/3~1/2 of the total thickness.

The alloy wear-resistant layer is mainly made of chromium alloy, with other alloy components such as manganese, molybdenum, niobium, and nickel added. The carbides in the metallographic structure are distributed in a fiber shape, and the fiber direction is perpendicular to the surface. The microhardness of cemented carbide can reach over HV1700-2000, and the surface hardness can reach HRC58-62.

Wear-resistant steel plates have high wear resistance and good impact performance. They can be cut, bent, welded, etc., and can be connected to other structures through welding, plug welding, bolting, etc., saving construction time. It is widely used in metallurgy, coal, cement, electricity, glass, mining, building materials, bricks and other industries. Compared with other materials, it has a higher cost performance and is favored by more and more people. Favored by industries and manufacturers.

Standards

| Grade | |||||

| Chemical Composition ( ≤ ) | NM300 | NM360 | NM400 | NM450 | NM500 |

| C | 0.23 | 0.25 | 0.3 | 0.35 | 0.38 |

| Si | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 |

| Mn | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| P | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 |

| S | 0.015 | 0.015 | 0.01 | 0.01 | 0.01 |

| Cr | 0.7 | 0.8 | 1 | 1.1 | 1.2 |

| Ni | 0.5 | 0.5 | 0.7 | 0.8 | 1 |

| Mo | 0.4 | 0.5 | 0.5 | 0.55 | 0.65 |

| Thickness (mm) | ≤80 | ≤80 | ≤80 | ≤80 | ≤70 |

| Tensile strength (MPa) | ≥1000 | ≥1100 | ≥1200 | ≥1250 | — |

| Elongation A (%) | ≥14 | ≥12 | ≥10 | ≥7 | — |

| Surface Brinell hardness (HBW) | 270-330 | 330-390 | 370-430 | 420-480 | ≥470 |

| Grade Comparison | |||||

| GB | NM300,NM360,NM400,NM450,NM500 | ||||

| SS | HARDNESS400, HARDNESS450, HARDNESS500, HARDNESS600 | ||||

| DIN | XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500 | ||||

| NBN | QUARD400, QUARD450, QUARD500 | ||||

| NF | FORA400, FORA500, Creusabro4800, Creusabro8000 | ||||

| JIS | JFE-EH360 , JFE – EH400 , JFE – EH500 , WEL-HARD400 , WELHARD500 | ||||

| SFS | RAEX400, RAEX450, RAEX500 | ||||

| Mechanical Properties | ||||||

| Material | Thickness(mm) | Strength of extension | Elongation | Impact energy(vertical) | BH(Brinell Hardness) | |

| ℃ | Akv/J | |||||

| NM300 | 6-80 | ≥1000 | ≥14 | -20 | ≥24 | 270-300 |

| NM360 | 6-80 | ≥1100 | ≥12 | -20 | ≥24 | 330-390 |

| NM400 | 6-80 | ≥1200 | ≥10 | -20 | ≥24 | 370-430 |

| NM450 | 6-80 | ≥1250 | ≥7 | -20 | ≥24 | 420-480 |

| NM500 | 6-70 | / | / | / | / | ≥470 |

| NM550 | 6-70 | / | / | / | / | ≥530 |

| HarDox450 | 5-50 | ≥1400 | 10 | -40 | ≥35 | 425~475 |

| HarDox500 | 5-50 | / | / | -40 | ≥30 | 450~540 |

| HarDox550 | 5-50 | / | / | -40 | ≥24 | 450~540 |

Standards and Classifications

| Standard | GB | ASTM | SSAB OXELOSUND | JIS |

| GRADE | NM360, NM400, NM450, NM500, NM550, NM600 | XAR400, XAR450, XAR500, XAR550 | HAR400, HAR450, HAR500, HAR550, HAR600 | NK-EH360, JFE-EH400, JFE-EH450, JFE-EH500 |

| Thickness | 6.0-200mm,etc | |||

| Width | 1500-4100mm,etc | |||

| Length | 2000-12000mm,etc | |||

| Standard | ASTM,AISI,JIS,GB, DIN,EN | |||

| Certification | ISO, SGS,BV | |||

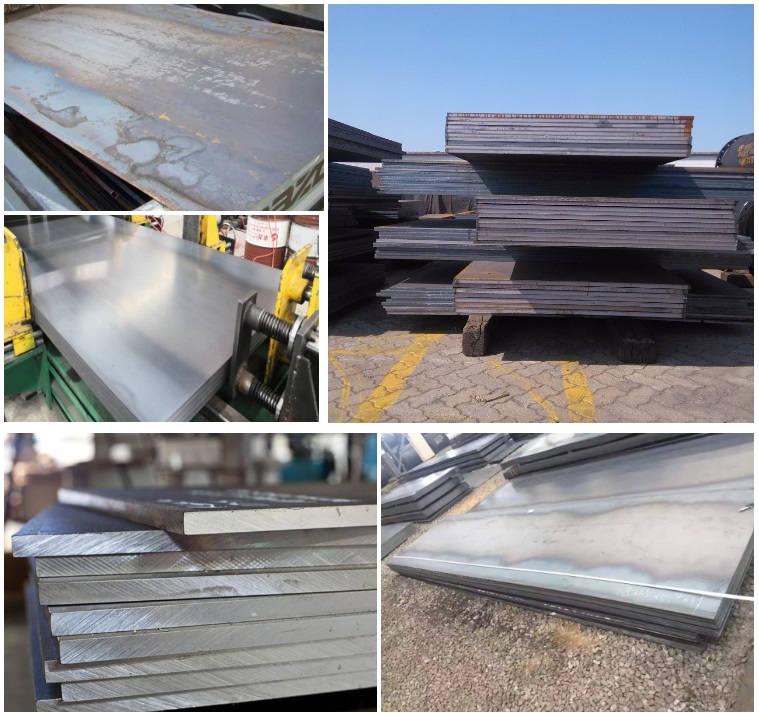

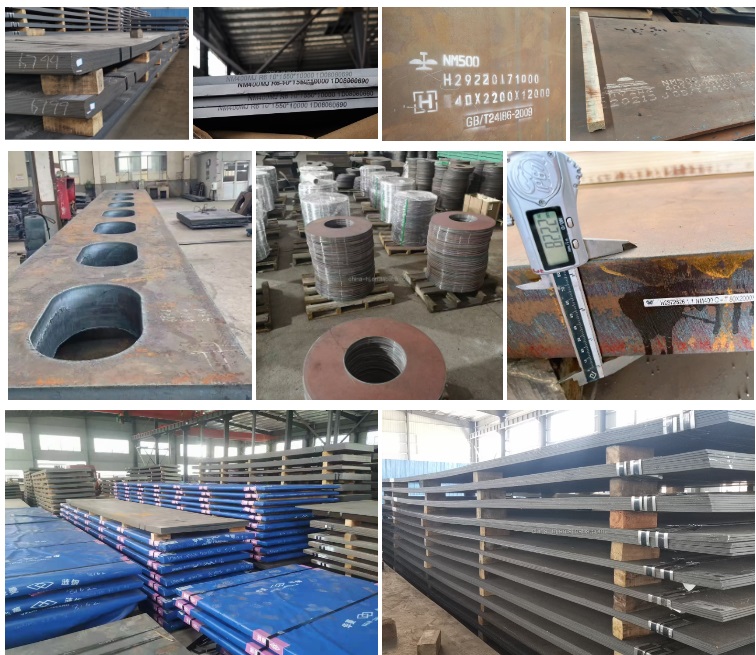

Product Display

Packing & Delivery

Shipping By Sea

1. Standard packaging

2. Packaging according to customer requirements

Reviews

There are no reviews yet.