Hot Rolled NO.1 Finish Stainless Steel Sheet

Hot-rolled stainless steel plate refers to stainless steel plate produced by hot rolling process, which has good plasticity and is generally medium and thick.

After the straight coil is processed by head cutting, tail cutting, edge cutting and multiple straightening, flattening and other finishing lines, it is cut or re-rolled to become: hot-rolled stainless steel plate, flat hot-rolled steel coil, longitudinally cut strip and other products. Hot-rolled stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion by acid, alkaline gas, solution and other media. It is an alloy steel that is not easy to rust.

Description

To buy the best hot rolled stainless steel sheets and get a quote, please contact us. Stainless steel sheets are divided into cold-rolled stainless steel sheet and hot-rolled stainless steel plates. The cold rolling process is to cold-press the steel plate into shape at room temperature, while the hot rolling process is to press the steel plate into shape at high temperature. There are obvious differences in the manufacturing process of cold-rolled stainless steel sheets and hot-rolled stainless steel plate.

Stainless steel sheet mainly include 201 stainless steel sheet, 304 stainless steel sheets, 316/316L stainless steel sheet, 430 stainless steel sheets, etc. In addition, we can also supply stainless steel profiles such as stainless steel pipes, stainless steel coils, and stainless steel bars.

Product Description

Hot-rolled stainless steel plate refers to stainless steel plate produced by hot rolling process, which has good plasticity and is generally medium and thick.

After the straight coil is processed by head cutting, tail cutting, edge cutting and multiple straightening, flattening and other finishing lines, it is cut or re-rolled to become: hot-rolled stainless steel plate, flat hot-rolled steel coil, longitudinally cut strip and other products. Hot-rolled stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion by acid, alkaline gas, solution and other media. It is an alloy steel that is not easy to rust.

Standards

GB/T4238, ASTM/ASME, JIS G4305, EN10088, BSEN10028, GB/T3280, GB/T4237

|

GB/T20878

|

JIS

|

ASTM

|

KS

|

BSEN

|

AS

|

CNS

|

t/m3 |

|

12Cr13

|

SUS403

|

403

|

STS403

|

—

|

403

|

403

|

7.75

|

|

20Cr13

|

SUS420J1

|

420

|

STS420J1

|

1.4021

|

420

|

420J1

|

7.75

|

|

30Cr13

|

SUS420J2

|

—

|

STS420J2

|

1.4028

|

420J2

|

420J2

|

7.75

|

|

10Cr17

|

SUS430

|

430

|

STS430

|

1.4016

|

430

|

430

|

7.70

|

|

68Cr17

|

SUS440A

|

440A

|

STS440A

|

—

|

440A

|

440A

|

7.70

|

|

06Cr19Ni10

|

SUS304

|

304

|

STS304

|

1.4301

|

304

|

304

|

7.93

|

|

022Cr19Ni10

|

SUS304L

|

304L

|

STS304L

|

1.4306

|

304L

|

304L

|

7.93

|

|

06Cr17Ni12Mo2

|

SUS316

|

316

|

STS316

|

1.4401

|

316

|

316

|

7.98

|

|

022Cr17Ni12Mo2

|

SUS316L

|

316L

|

STS316L

|

1.4404

|

316L

|

316L

|

7.98

|

|

06Cr18Ni11Ti

|

SUS321

|

321

|

STS321

|

1.4541

|

321

|

321

|

7.93

|

|

06Cr18Ni11Nb

|

SUS347

|

347

|

STS347

|

1.455

|

347

|

347

|

7.98

|

Specification

(1) Thin stainless steel sheet (0.2mm-4mm)

(2) Stainless steel middle plate (4mm-20mm)

(3) Stainless steel thick plate (20mm-60mm)

(4) Extra thick stainless steel plate (60-115mm)

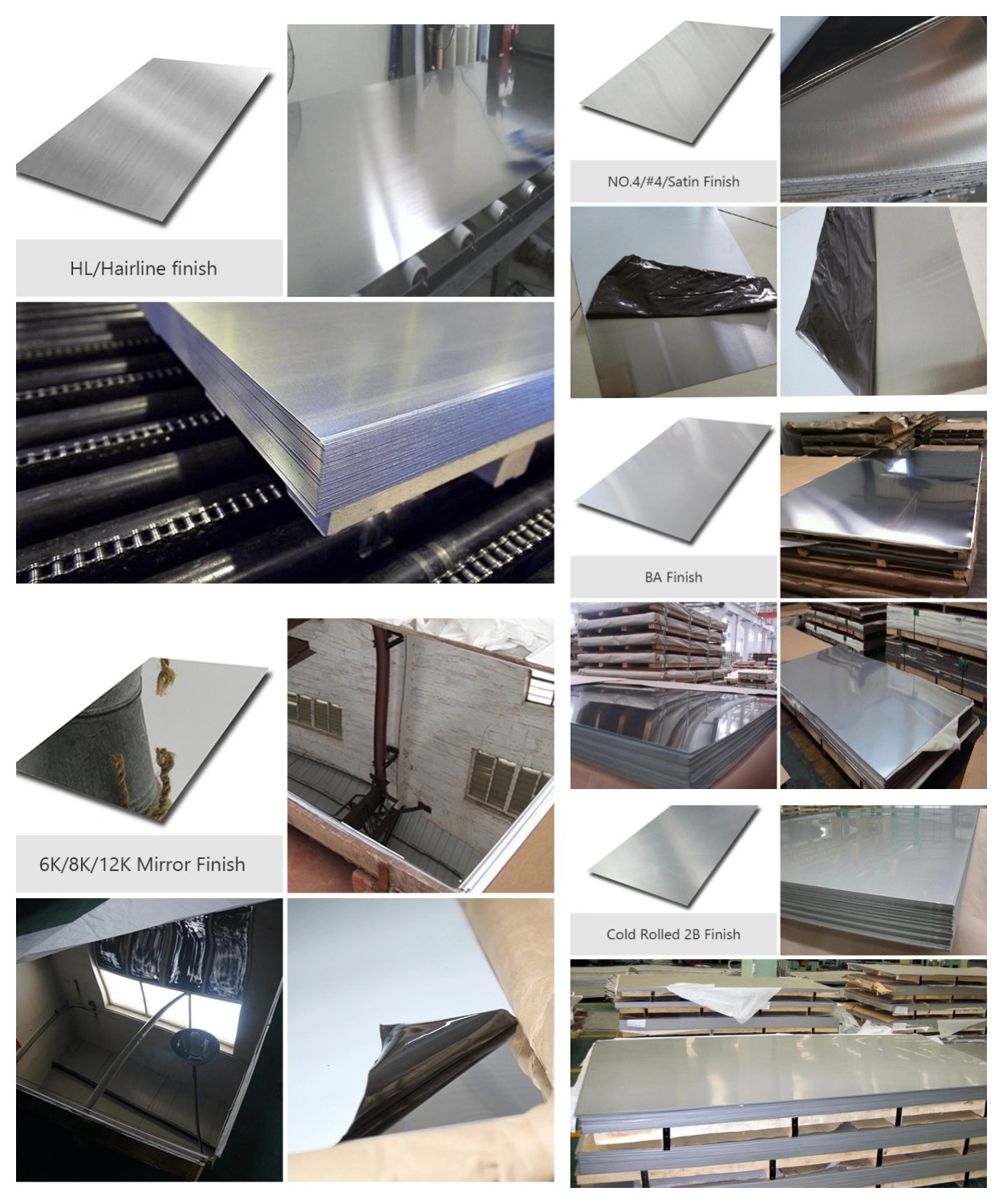

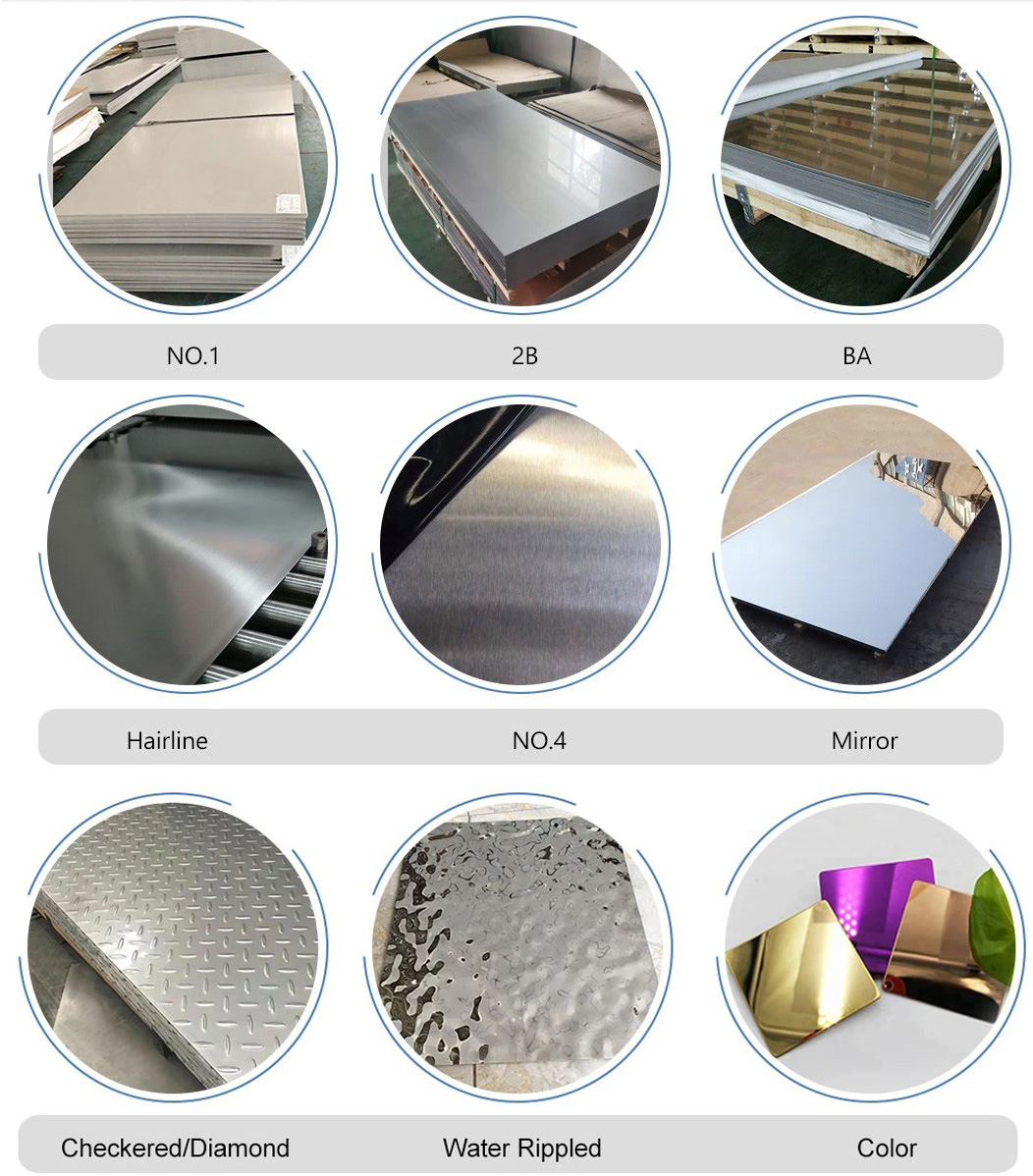

Surface

NO.1, NO.2D, NO.2B, BA, NO.3, NO.4, NO.240, NO.320, NO.400, HL, NO.7, NO.8

Standards and Classifications

| All specifications products can be customized according to customer requirements | ||||

| Product Name | Stainless Steel Sheet | |||

| Material | ①Mainly:201, 202, 304, 304L, 304H, 316, 316L,316Ti,2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 etc ②300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,347 ③200series:201,202,202cu,204 ④400series:409,409L,410,420,430,431,439,440,441,444 ⑤Others:2205,2507,2906,330,660,630,631,17-4ph,17-7ph, S318039 904L,etc ⑥Duplexstainless steel:S22053,S25073,S22253,S31803,S32205,S32304 ⑦Special Stainless Steel:904L,347/347H,317/317L,316Ti,254Mo |

|||

| Thickness | 0.1~200 mm,or customized | |||

| Length | 100~12000 mm,or customized | |||

| Width | 10~2000 mm,or customized | |||

| Standard | ASTM, JIS, GB, AISI, DIN, BS,EN,ETC,etc. | |||

| Finish | 2B, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted | |||

| Packing | Industry standard packaging or according to client’s requirement | |||

| Payment terms | 30%T/T in advance, the balance against the B/L copy | |||

| MOQ | 3 TONS,can be customized according to your requirements. | |||

| Delivery time | Fast delievery in 7 days,up to order quantity | |||

| Application | Used in the production of electrical components, connectors, radiators,Conductive base materials,automobile water tanks, heat sinks, cylinder fins, etc. | |||

| Surface Finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

| STAINLESS STEEL CHEMICAL COMPONENT | ||||||||

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 | ≤0.75 | 5.5-7.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 16.0-18.0 | – |

| 202 | ≤0.15 | ≤1.0 | 7.5-10.0 | ≤0.06 | ≤0.03 | 4.-6.0 | 17.0-19.0 | – |

| 301 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 6.0-8.0 | 16.0-18.0 | – |

| 302 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 8.0-10.0 | 17.0-19.0 | – |

| 304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 8.0-10.5 | 18.0-20.0 | |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-13.0 | 18.0-20.0 | |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 12.0-15.0 | 22.0-24.0 | |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.03 | 9.0-13.0 | 17.0-19.0 | – |

| 904L | ≤2.0 | ≤0.045 | ≤1.0 | ≤0.035 | – | 23.0-28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.80 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤0.03 | 0.19-0.22 | 0.24-0.26 | – |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤0.03 | – | 11.5-13.5 | – |

| 430 | 0.12 | ≤0.75 | ≤1.0 | ≤0.040 | ≤0.03 | ≤0.60 | 16.0-18.0 | – |

Product Display

Packing & Delivery

Shipping By Sea

1. Standard packaging

2. Packaging according to customer requirements

Reviews

There are no reviews yet.